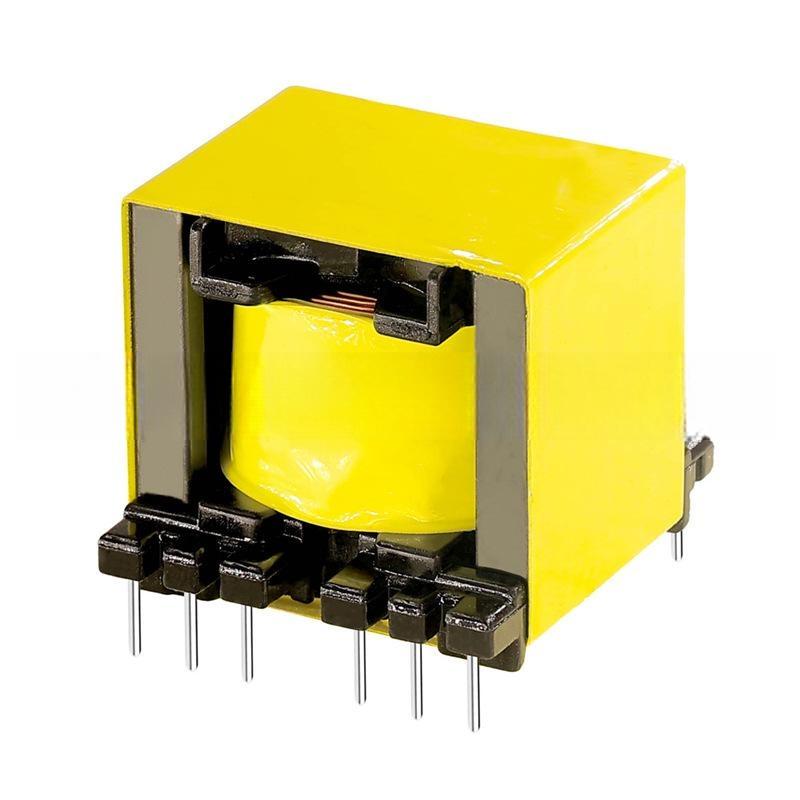

Custom Transformer refers to a transformer that is specially designed and manufactured according to specific requirements when standard models are not suitable for a particular circuit design. Since every engineer may have a different understanding of the circuit, the design of the circuit board often requires transformers tailored to meet unique specifications and functionalities. Therefore, we manufacture them based on the customers’ individual requirements.

Why is a Custom Transformer Needed?

Standard Transformers may not meet the customer’s requirements. A Custom Transformer is tailored based on various factors such as the customer’s desired electrical performance, physical dimensions, cost and application environment. At the same time, it must ensure product reliability and efficiency.

Process and Key Considerations for Custom Transformer Design.

1.Requirement Communication:

Before starting the customization, we communicate with the customer to confirm key details, such as application environment and circuit parameters. This helps us fully understand the transformer’s specific requirements.

2. Design Proposal:

After understanding the customer’s needs, we provide a suitable transformer design plan. We also perform calculations and simulations to ensure the transformer will be stable, reliable and efficient.

3. Sample Prototyping:

Based on the approved design, we create prototype samples and develop detailed manufacturing instructions.

4. Sample Verification:

The prototype is sent to the customer for function testing and PCB compatibility testing.If the sample fails to meet the design requirements, we revise and resend samples until approved.

5.Production:

Once the design is finalized and approved, we proceed to the mass production.

6.Quality Inspection:

Throughout production, we conduct strict testing and inspection to ensure product quality and performance meet expectations.

Key Points to Consider when Customizing a transformer.

Custom transformer design should be carefully planned, with all technical parameters confirmed to ensure cost control and optimal performance-to-price ratio.

Before customization, it’s important to clarify actual needs and budget constraints to avoid unnecessary economic loss caused by inaccurate design or overly complex specifications.

High-quality raw materials and advanced manufacturing equipment must be used to ensure the resulting transformers is reliable ,high-performance and durable.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.