Established in 2013, Shenzhen Kunyo Technology specializes in the design and manufacture of custom magnetic components.

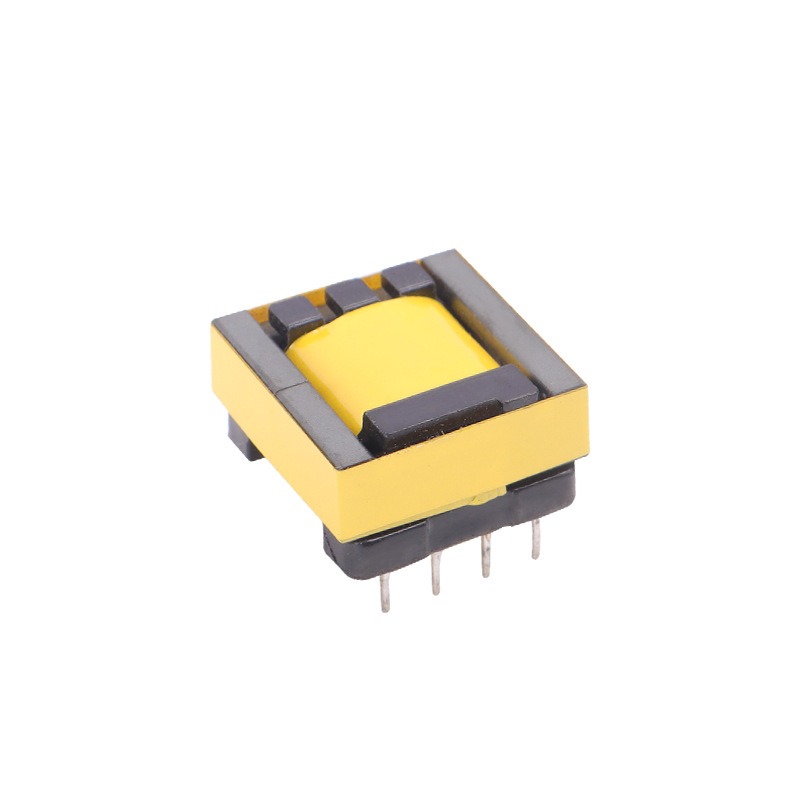

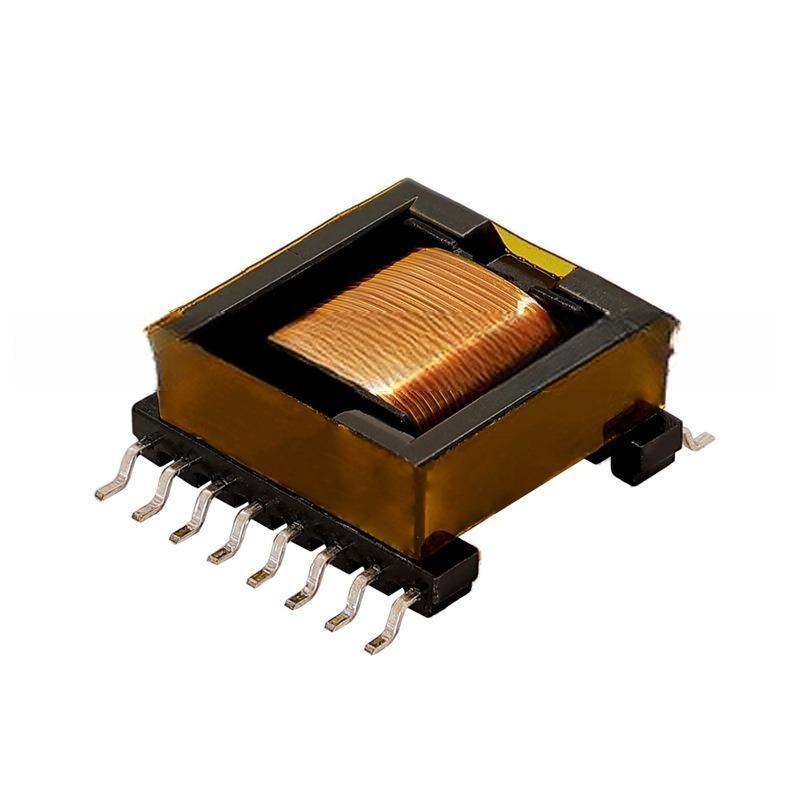

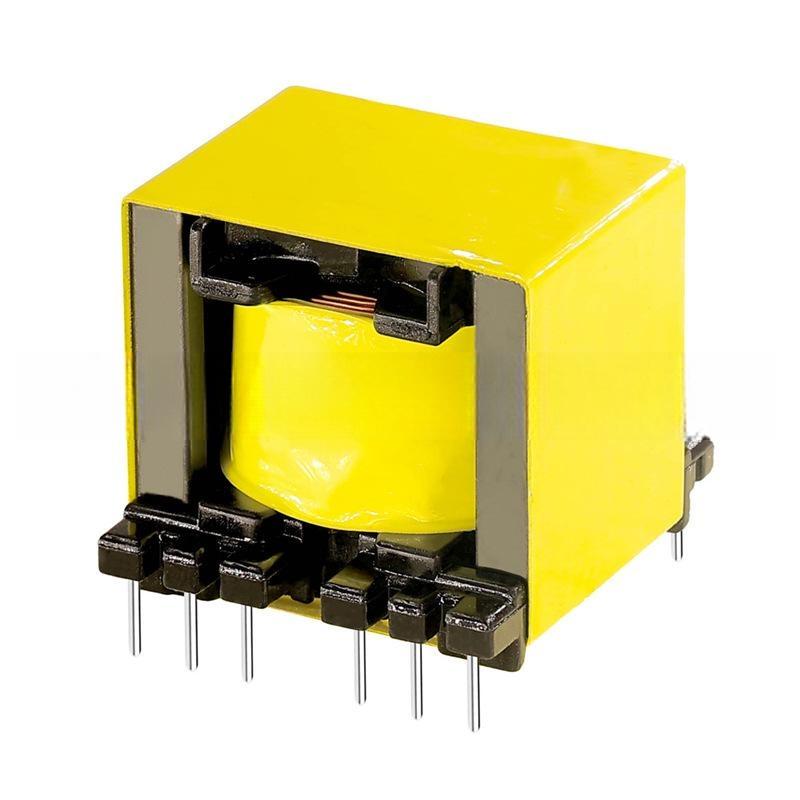

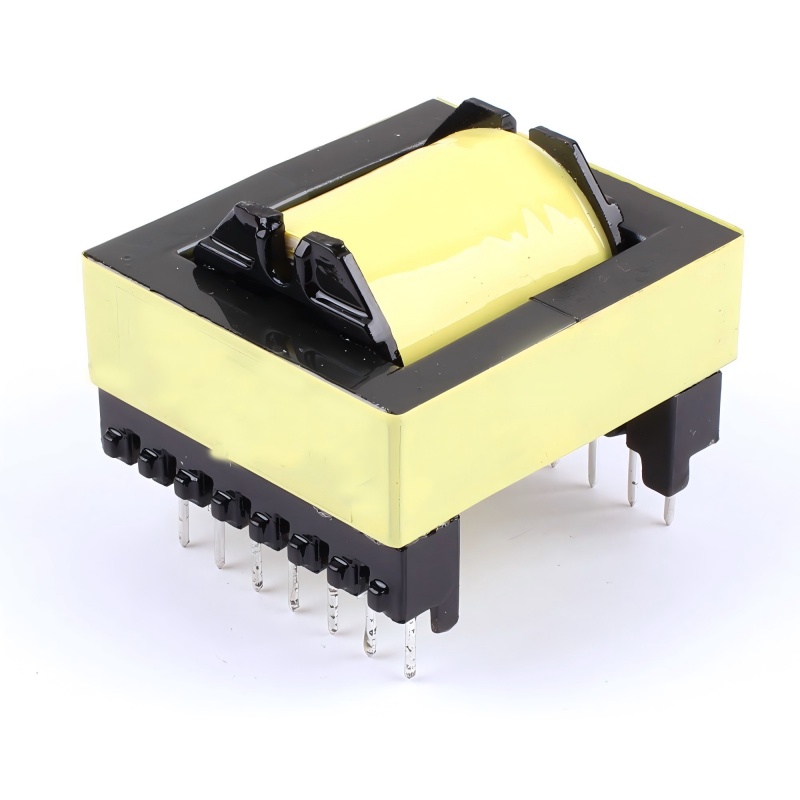

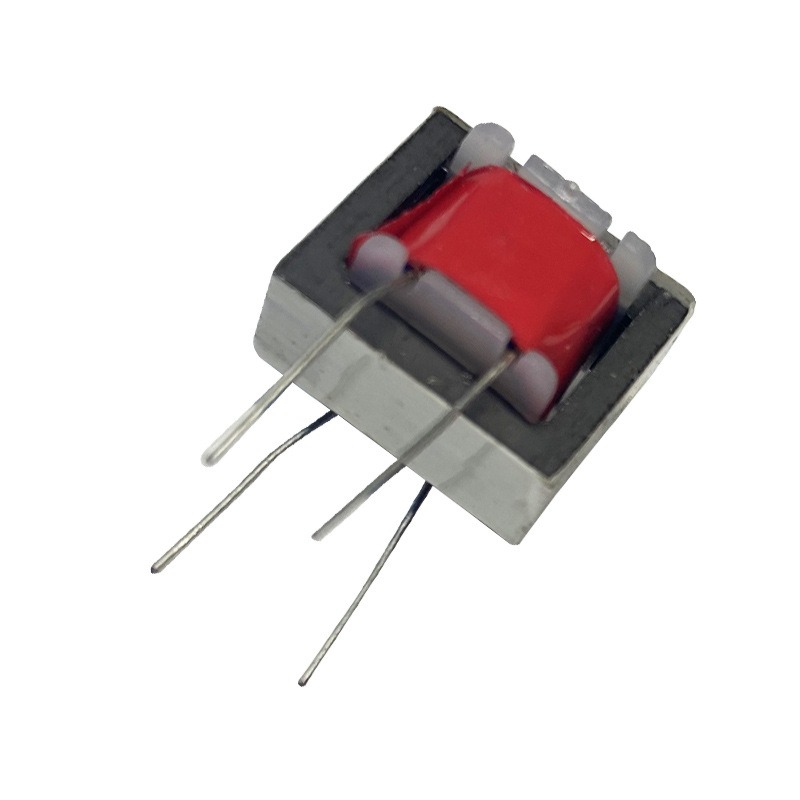

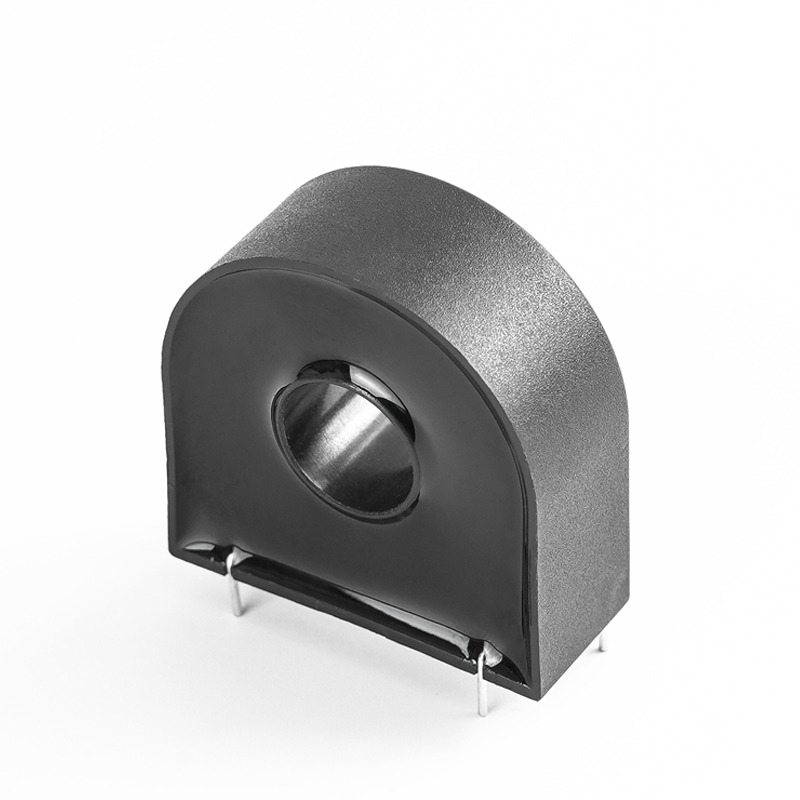

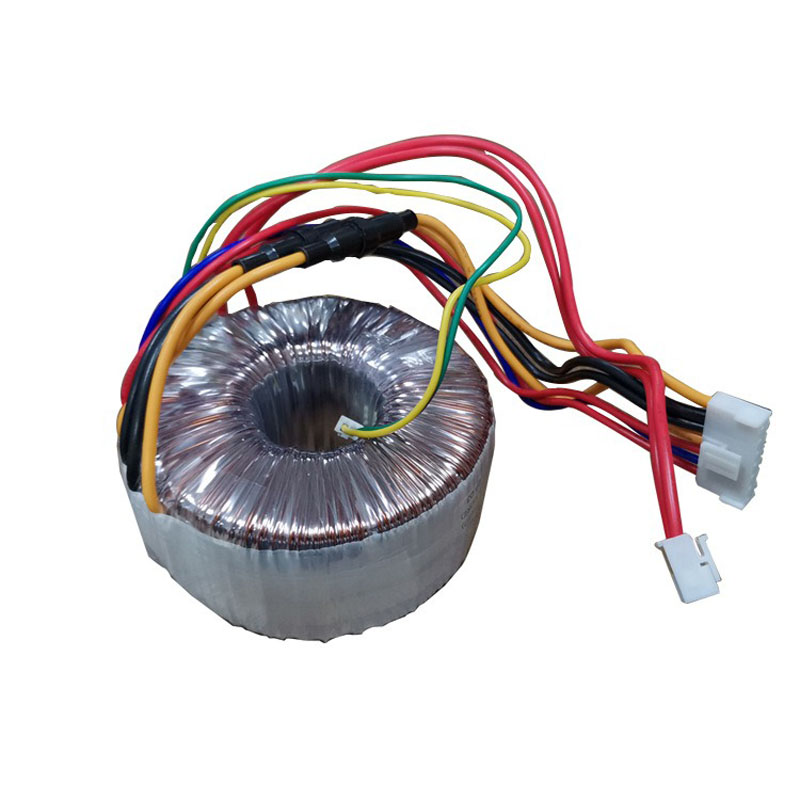

Our product range covers a wide variety of magnetic solutions, including high-frequency transformers, flyback transformers, switching power transformers, audio transformers, low-frequency power transformers, step-up transformers, current sense transformers, surface mount transformers, pulse transformers, and PCB transformers.

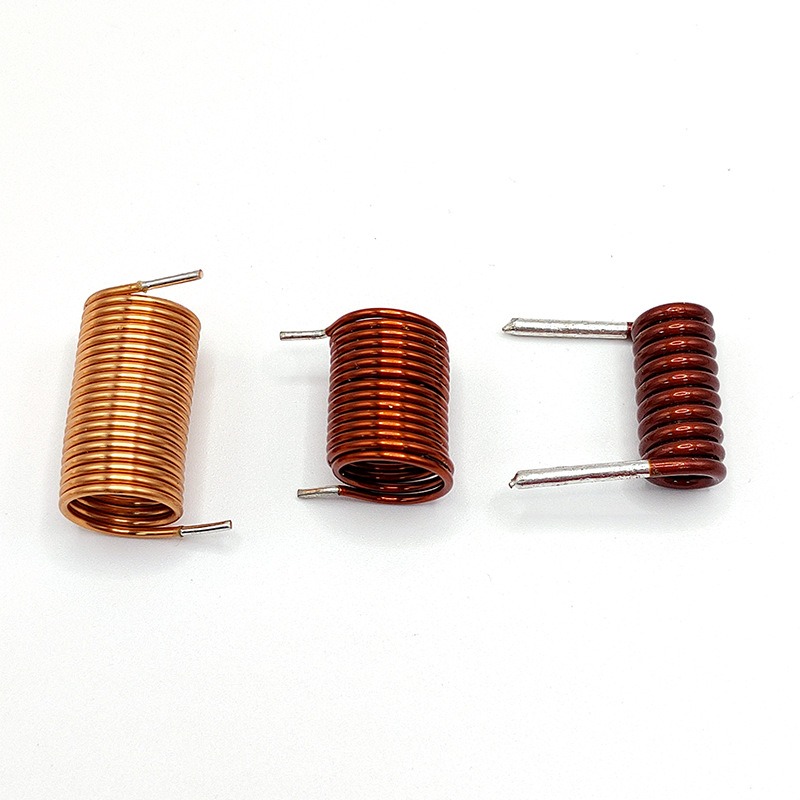

We also produce inductors, common mode chokes, power inductors, coils, power line filters, and EMI filters, providing complete magnetic component solutions for various electronic applications.

As the Original Manufacturer of Transformer and Inductor products, we have all the manufacturing machines in our factory.

Design the custom products based on the customer specification and we can make sure that your custom magnetic components are built to the correct specifications.

We adhere to a strict quality standards. And we put customers at heart during the production process, and ensure production quality meets the requirement of customers.

Time is money and efficiency. Our team can respond directly to any specific customer needs and our sales team can respond quickly in 24 hours.

We can deliver the goods on time and satisfy customer’s expectation. And we usually carry a large stock of raw materials that enables us to deliver prototypes or finished products on time.

Our company occupies an area of 3,000 square meters. With over a decade of experience in engineering development and design, we are fully equipped to deliver high-quality magnetic components to our customers.

Our products are widely applied in home appliances, consumer electronics, robotics, smart furniture, monitoring systems, audio equipment, scientific research, aerospace, electric vehicles (EVs), and UPS power systems, among many other fields.

Custom Transformer refers to a transformer that is specially designed and manufactured according to specific requirements when standard models are not suitable for a particular circuit design. Since every engineer may have a different understanding of the circuit, the design of the circuit board often requires transformers tailored to meet unique specifications and functionalities. Therefore, we manufacture them based on the customers’ individual requirements.

The application of high frequency transformer is extremely wide. Transformers are used in all electronic products. Its principle is easy, but transformer winding technology will have different needs due to different applications (different uses) .how to deal with the transformer short circuit incident ? What should be the first thing to consider when encountering problems?

When engineers design magnetic components on circuit boards, there are many factors which will result in they need to customize transformers, such as:

Special power requirements.

Insufficient circuit board space.

Product performance requirements

ambient temperature

Special installation dimensions

Interfaces are required: such as terminals and leads.

An inductor is a passive component that generates inductive reactance through the principle of electromagnetic induction. Based on differences in structure and working principle, inductors can be categorized into several types, including air-core coils, iron-core coils, transformers, and coupled coils. The key parameters of inductor coils include inductance value, coupling coefficient, time constant, and energy loss. Common inductor coils include high-frequency inductors, low-frequency inductors, transformer coils, and coupled coils. These components play an important role in electronic circuits and power systems, and are applied in different fields according to their distinct characteristics.

Stop thinking more,pls just fill out below blank form and send us an inquiry, there will be a professional team about custom magnetic products . And they will contact you to have an quick answer about your questions and pricing.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.