Custom PCB transformers are engineered to provide reliable voltage conversion, electrical isolation, and efficient signal transfer directly on printed circuit boards. Designed with optimized size, high efficiency, and long-lasting durability, these transformers are ideal for modern electronic devices where space constraints and high performance are critical. They ensure stable operation in demanding applications, from precision power supplies to high-frequency communication devices.

At Shenzhen Kunyo Tech, we specialize in designing and manufacturing PCB transformers tailored to your exact specifications. Whether your project involves power supplies, telecommunications, industrial control systems, or consumer electronics, our custom transformers are built to deliver maximum performance, enhanced safety, and long-term operational stability. Every transformer is carefully engineered to meet your specific voltage, current, and frequency requirements, ensuring compatibility with your unique application.

We offer both standard PCB transformer designs and fully customized solutions. Our engineering team works closely with clients to address special requirements, such as specific winding configurations, core materials, insulation standards, and mounting options. By collaborating from concept to production, we ensure that every custom transformer not only meets but often exceeds performance expectations.

Choosing Shenzhen Kunyo Tech for your PCB transformer needs guarantees high-quality components optimized for space, efficiency, and reliability, helping you achieve superior device performance, reduced energy loss, and improved long-term system stability

PCB transformers, also known as printed circuit board transformers, are transformers mounted directly on PCB boards. Custom PCB transformers are essential components in electronic devices, typically used to convert voltage and current within circuits.

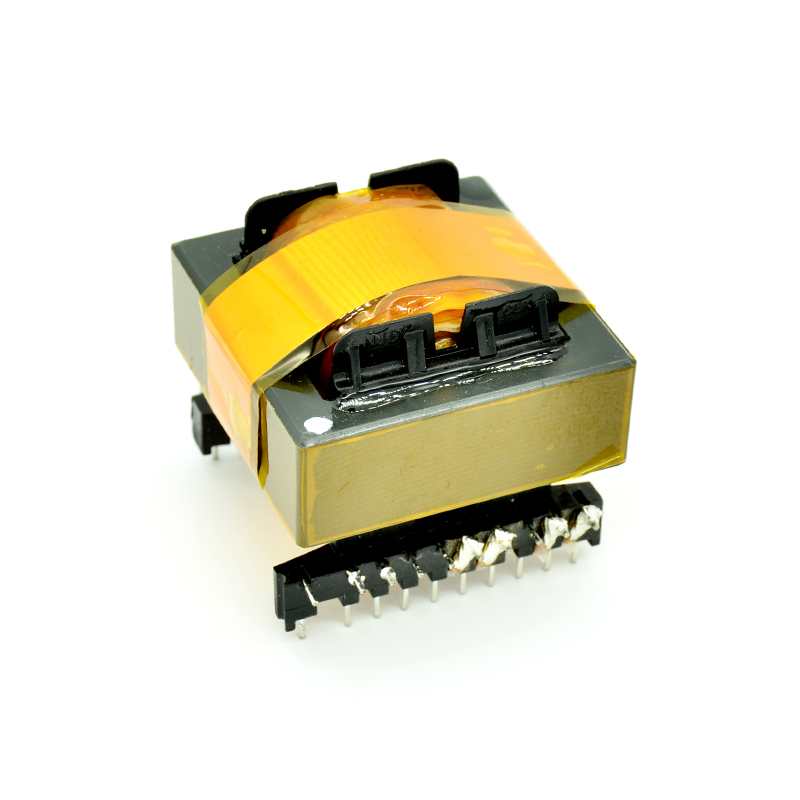

A transformer consists of a primary coil and a secondary coil, coupled magnetically through their shared magnetic field. Custom PCB transformers are usually installed on circuit boards together with other components, playing a critical role in overall circuit operation. They enable power transfer between two circuits, with one of their most important advantages being the ability to provide electrical isolation across different voltage levels.

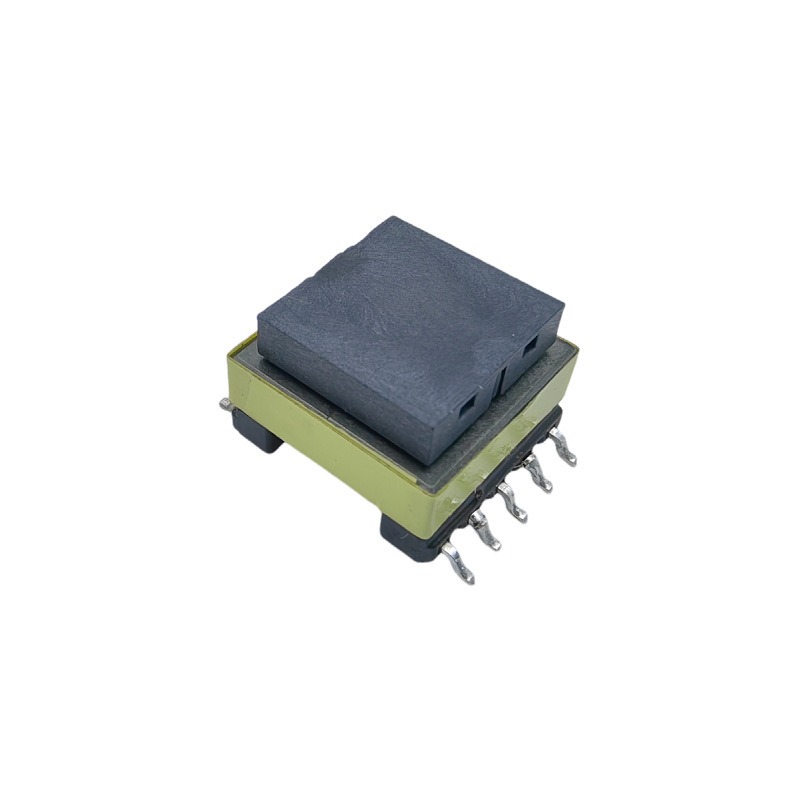

The size and specifications of a transformer depend on the requirements of the electronic device, and they are available in various shapes and dimensions.

If you are planning to design a custom PCB transformer, it is important to focus on several key factors such as rated voltage and current, frequency range, installation options, core materials, winding techniques, and insulation requirements. These elements directly affect the performance of the transformer and its compatibility with the intended application.

Selecting the proper transformer rating is vital for safe and efficient performance. Always start by matching the transformer’s primary and secondary voltage with your system requirements. Then, ensure the current capacity is within the safe limits of the windings to avoid overheating and power loss.

It is also important to check the power rating (VA), efficiency, and thermal performance to guarantee stable operation, especially under peak load conditions. Choosing a transformer with a small safety margin allows your equipment to handle fluctuations more reliably.

By selecting a transformer with the correct voltage, current, and power rating, you can achieve stable power delivery, reduced noise, longer service life, and reliable performance across a wide range of applications.

The frequency range of a custom PCB transformer plays a critical role in determining its overall performance, efficiency, and reliability. Transformers that are specifically designed for a targeted frequency range can achieve optimal energy transfer, minimal signal loss, and improved voltage regulation, compared to transformers designed for a broader, less-specific operating range.

By carefully matching the transformer design to the operating frequency of your circuit, engineers can reduce core losses, minimize heat generation, and improve the efficiency of the power supply or signal conversion. This is especially important in high-frequency applications such as switch-mode power supplies (SMPS), DC-DC converters, communication devices, and other precision electronics, where even small losses can impact overall system performance.

In addition, selecting a transformer optimized for the intended frequency ensures better signal integrity, lower electromagnetic interference (EMI), and longer component lifespan. Custom PCB transformers designed with the correct frequency range not only improve efficiency but also enhance the stability and reliability of your entire electronic system.

For designers and manufacturers seeking high-performance custom PCB transformers, focusing on the right frequency specification is essential to achieve maximum efficiency, minimal energy loss, and superior operational reliability.

Space constraints are often a decisive factor when selecting a transformer for PCB applications. In modern electronic devices, limited board space or tight enclosure dimensions can significantly influence the choice of transformer, making compact and efficient designs essential for optimal system performance.

Custom PCB transformers are designed to address these space limitations while maintaining high performance and reliability. Depending on your specific application and assembly requirements, they can be manufactured in a variety of configurations, including surface-mount (SMT), through-hole, or fully customized designs. This flexibility allows engineers to optimize the layout of their printed circuit boards, reduce footprint, and ensure that the transformer fits seamlessly into the overall design without compromising electrical performance.

In addition to physical size, proper selection of a transformer also considers thermal performance, current handling, and voltage ratings, which are all critical for safe and efficient operation in space-constrained applications. By choosing a custom PCB transformer optimized for both size and performance, designers can achieve a compact, reliable, and high-efficiency solution that meets the demands of modern electronics.

For applications in power supplies, communication devices, automotive electronics, and industrial systems, selecting the right-sized transformer ensures not only compatibility with PCB layout constraints but also long-term stability, reduced energy loss, and enhanced device reliability.

The choice of core material is a critical factor in designing custom PCB transformers, as it directly affects performance, efficiency, and reliability. Key considerations include magnetic saturation, permeability, and core losses, all of which determine how effectively the transformer can transfer energy while minimizing heat and energy loss.

For instance, MnZn ferrite cores with high permeability are widely used in high-performance PCB transformers. Their high permeability allows for efficient magnetic flux conduction, which significantly improves electromagnetic conversion efficiency, often achieving levels above 90%. This not only reduces energy losses but also helps maintain stable voltage regulation, low noise, and minimal thermal buildup, even under high-frequency operation or high-current loads.

Choosing the right core material also ensures that the transformer can operate safely within the intended voltage and frequency ranges, preventing magnetic saturation, overheating, or signal distortion. Additionally, optimized core selection can reduce the overall size of the transformer, making it ideal for compact PCB layouts and space-constrained electronic devices.

By selecting high-quality ferrite or other advanced core materials, designers can achieve high-efficiency, low-loss, and long-lasting custom PCB transformers, suitable for a wide range of applications including power supplies, SMPS, communication devices, automotive electronics, and industrial control systems.

The winding method of a custom PCB transformer plays a crucial role in determining its efficiency, size, weight, and overall performance. Different winding techniques, such as layered, interleaved, or bifilar winding, can significantly influence parameters like leakage inductance, coupling efficiency, thermal performance, and electromagnetic compatibility (EMC).

During the transformer design process, it is essential to carefully balance rated power, space limitations, and specific application requirements. For example, tightly wound coils can reduce transformer size and improve coupling efficiency, but may increase manufacturing complexity or thermal challenges. Conversely, certain winding methods can minimize core losses and enhance efficiency but may require more PCB space.

By developing a tailored winding solution, engineers can optimize the transformer for maximum performance while meeting size and weight constraints. This ensures stable voltage output, reduced energy loss, lower electromagnetic interference, and enhanced reliability across a wide range of applications.

Optimized winding methods are especially important for high-frequency switch-mode power supplies (SMPS), DC-DC converters, automotive electronics, and compact communication devices, where both efficiency and space savings are critical. Selecting the right winding approach not only improves performance but also contributes to longer operational life and better thermal management of the transformer.

Proper packaging and insulation are essential factors in the design and performance of custom PCB transformers, directly impacting safety, reliability, and operational efficiency. High-quality insulation prevents electrical short circuits between windings and other conductive parts, ensuring stable voltage delivery and protecting sensitive components in the circuit.

In addition to electrical safety, effective packaging and insulation help minimize noise interference and electromagnetic coupling, which is critical for maintaining signal integrity in high-frequency or communication applications. They also safeguard the transformer from environmental hazards, such as dust, moisture, and temperature variations, which can degrade performance or shorten the component’s lifespan.

By combining robust insulation materials with secure packaging methods, manufacturers can ensure that the transformer operates smoothly under continuous, high-current, or high-frequency conditions. This not only enhances energy efficiency and thermal stability but also improves the overall durability and reliability of the device.

For applications in switch-mode power supplies (SMPS), automotive electronics, communication systems, and industrial controls, proper packaging and insulation are critical to achieving long-lasting, high-performance, and safe custom PCB transformers. Choosing the right insulation and encapsulation methods allows designers to meet both regulatory safety standards and demanding operational requirements.

Custom PCB transformers play a vital role within circuit boards and are widely used in electronic products and communication systems. Thanks to their compact size, they are an ideal choice for space-limited and densely packed circuits.

Custom PCB transformers are essential for power supply, signal processing, and voltage regulation in electronic devices, and they are commonly found in audio amplifiers, LED lighting, battery chargers, and switch mode power supplies. Their compact design helps maximize available space while ensuring optimal functionality. Moreover, they enable efficient power transmission with minimal losses, providing an energy-saving and cost-effective solution.

With the growing demand for intelligent devices, the advantages of custom PCB transformers make them a reliable solution for power management in electronics, and their applications are expected to expand even further in the future.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.