A high frequency transformer functions as a transducer and is specifically designed to operate at high frequencies. The primary difference between high frequency and low frequency transformers lies in their operating frequency range. Due to the intense energy transfer in high-frequency magnetic fields, material selection differs significantly.

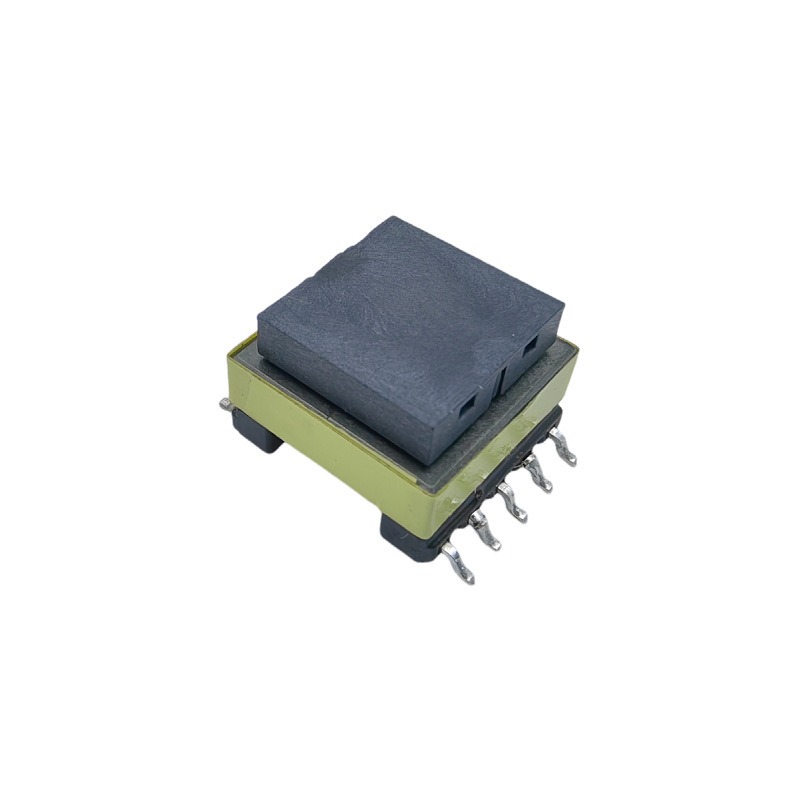

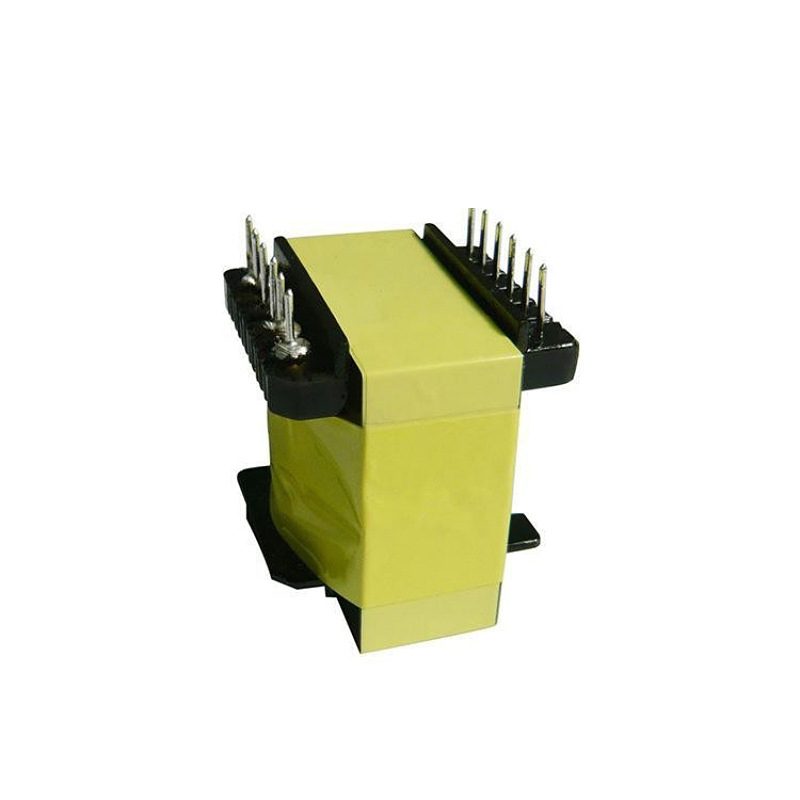

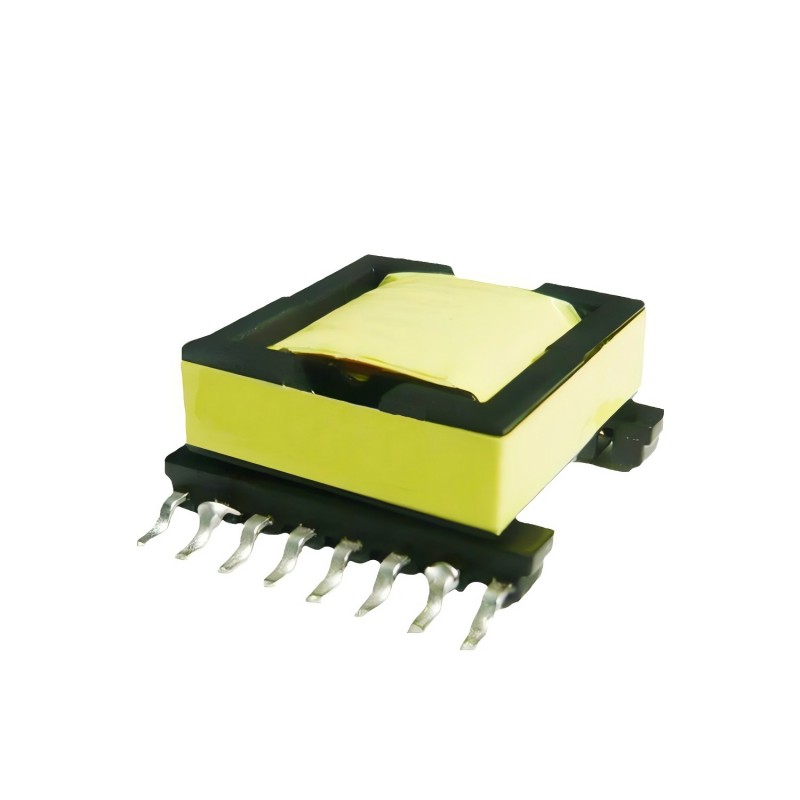

These transformers typically use high-frequency ferrite cores to ensure optimal magnetic performance. While both high and low frequency transformers operate based on the principle of electromagnetic induction, the design and materials vary to suit different frequency ranges.

High frequency transformers are known for their compact size, light weight, and ability to function efficiently at high switching speeds. They are widely used across a broad range of applications, including telecommunications, computers, medical devices, industrial automation, aerospace, and automotive electronics.

A high frequency transformer is a transformer with a working frequency higher than the standard working frequency (50/60Hz). A high frequency transformer is a static electrical device that mainly transmits electrical energy between two or more circuits through electromagnetic induction.

High frequency transformers are mainly used in high frequency switching power supplies, high frequency inverter power supplies and high frequency inverter welding machines,etc.

With the increasing use of electronic devices and growing market demand, the need for high-frequency transformers continues to rise. Shenzhen Kunyo has many years of experience in the design and manufacturing of electronic transformers, enabling us to meet our customers’ unique performance requirements.

High-frequency transformers offer several advantages, including high power density, compact design with reduced material usage, and strong customization potential based on specific applications. However, to meet customer requirements effectively, careful attention must be given to design principles during the development process.

Shenzhen Kunyo’s custom high-frequency transformers are cost-effective and tailored to meet specific customer needs. We can help optimize designs to save PCB space and offer a variety of material options based on performance requirements. Our high-frequency transformers are widely used in a range of high-tech applications and are capable of delivering maximum power even in compact spaces.

Leakage inductance in a high-frequency transformer results from the incomplete magnetic coupling between the primary and secondary windings. Not all magnetic flux produced by the primary winding links with the secondary winding. The portion of flux that does not couple effectively generates what is known as leakage inductance.

Distributed capacitance refers to the unintended capacitance that forms between turns of a transformer winding, between different layers of the same winding, between separate windings, and between the winding and any shielding layers.

In high-frequency transformer design, the primary winding is typically placed closest to the core. This positioning minimizes the length of each turn, which helps reduce distributed capacitance and improves overall performance.

In high-frequency transformer design, it is common to add two or three layers of insulating tape between the primary and secondary windings. This helps reduce the distributed capacitance between the windings while also enhancing the insulation strength, ensuring improved electrical isolation and safety.

To effectively address interference issues in high-frequency transformers, copper foil is often added between the windings or around the outermost layer of the magnetic core to enhance electromagnetic shielding

In high-frequency transformer design, insulation and withstand voltage are critical factors. If the product requires a high withstand voltage or if the designed safety clearance is insufficient, measures such as adding insulating barriers, tapes, sleeves, and applying impregnation processes can be used to increase the voltage resistance and enhance the safety distance between the primary and secondary windings.

Before shipment, we will conduct 100% testing on each high-frequency transformer product and attach a test report with the goods for traceability.

We are ISO9001 certified, ensuring the highest quality in the industry.

Our high voltage and high frequency transformers can be manufactured in accordance with UL, CUL, VDE and CE standards.

A high-frequency transformer is designed to operate at elevated frequencies and serves as an energy conversion device. At these higher frequencies, traditional silicon steel cores experience significant eddy current losses, as the magnetic domains cannot respond quickly enough to the rapid switching. To address this, high-frequency transformers typically utilize ferrite cores, which are better suited for minimizing losses in high-frequency environments.

The key difference between high-frequency and low-frequency transformers lies in their operating frequency, which influences both material selection and design approach. Despite this, both types share the same fundamental working principle—transferring energy through electromagnetic induction.

Due to their frequency-specific characteristics, high-frequency transformers must be used in circuits where the excitation frequency aligns with their design parameters. Likewise, low-frequency transformers are only appropriate for low-frequency applications. Using them outside their intended frequency range can result in poor performance or even component failure.

At a given energy transfer level, a transformer operating at a higher frequency can transmit smaller energy pulses more frequently. This allows for fewer coil windings, less core material, and a more compact structure. As a result, high-frequency transformers are typically smaller, lighter, and more space-efficient than low-frequency transformers, which require larger cores and more turns to handle the same power output.

High-frequency transformers with the small size characteristics, can be applied in a wide range of large or small applications.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.