Air Coil Inductors: Versatile Components for Electromagnetic Applications

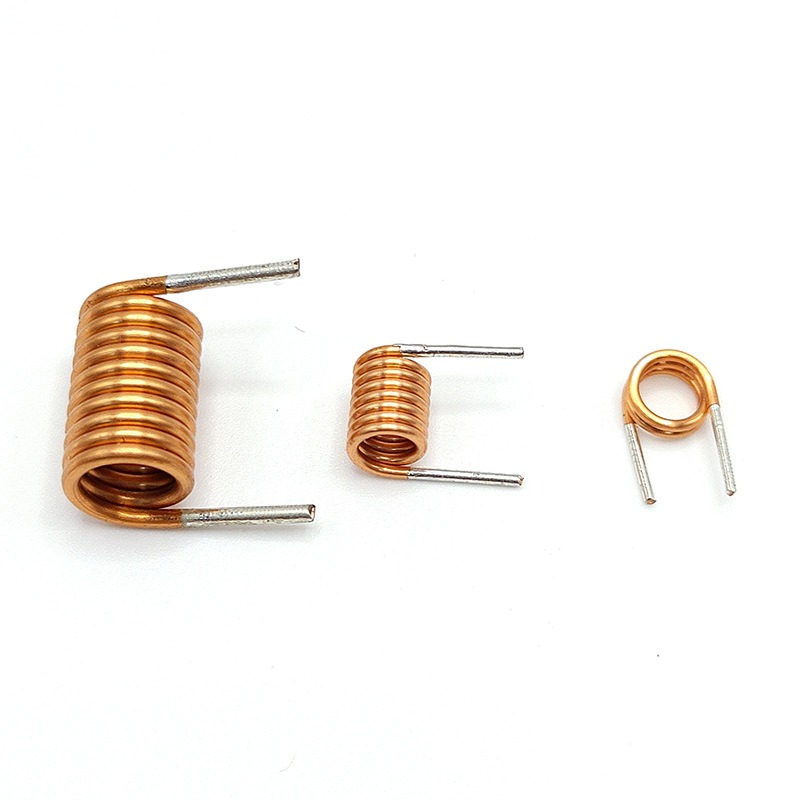

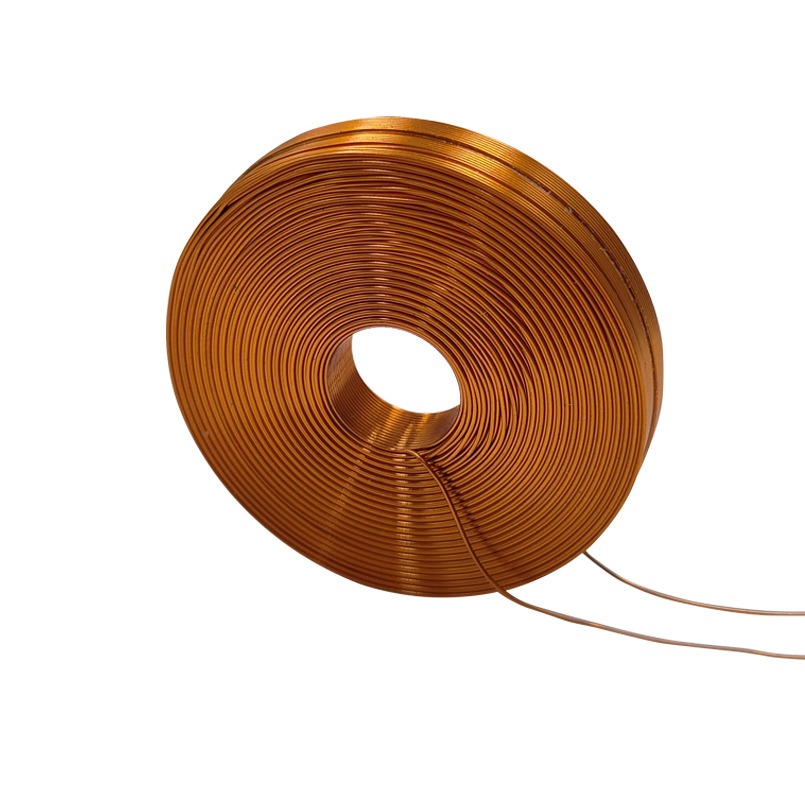

An air coil inductor, also known as an air core inductor, is a type of inductor that does not contain a magnetic core. Instead, the coil is wound with air as its core, offering minimal magnetic interference and high-frequency performance. These coils are typically made from insulated copper wire, with options for stripped, non-stripped, tinned, or bare ends depending on application requirements.

Air coil inductors operate on the principle of electromagnetic induction. When placed in a magnetic field, a coil can cut through magnetic lines of force and convert that magnetic energy into electrical energy. This fundamental principle is widely applied in the creation of devices such as relays, motors, generators, wireless transmitters, and speakers.

While coils can be made from various conductive materials—such as copper, aluminum, iron, or even gold—the choice of core significantly affects performance. Adding a magnetic core can enhance inductance, but when a non-magnetic center, such as plastic or air, is used, it forms an air-core coil.

Air-core inductors are highly versatile and can be manufactured in a variety of shapes—including round, square, elliptical, or other custom geometries—to suit specific design and performance needs. Their low core loss and high linearity make them especially suitable for RF, high-frequency, and precision electronic applications.

Air Coil Inductors (also known as air core inductors) are inductive components that do not use a magnetic core—air serves as the medium within the coil. These inductors are typically made from copper wire, either insulated or bare, with options for stripped, non-stripped, tinned, or untinned ends depending on application requirements.

Air-core inductors are widely utilized due to their ability to store energy, conduct direct current (DC), block alternating current (AC), and support electromagnetic induction. Their applications span a broad range of fields, including inductive sensing, focusing systems, magnetic cards and heads, high-current and low-voltage devices, industrial automation, household appliances, automotive electronics, SMT assembly, mobile communications, wireless transmission systems, GPS/navigation units, power regulation, amplifiers, power supplies, and filtering circuits in various electronic devices and components.

Inductance (L) is a fundamental property of a coil that does not depend on the current flowing through it. It is typically defined and specified by a designated value under standard conditions.

The opposition an inductor presents to alternating current (AC) is known as inductive reactance (XL), measured in ohms (Ω). In an air-core coil, a self-induced electromotive force (EMF) is generated that resists changes in current through the coil. This inductive reactance restricts the flow of AC and is calculated using the formula: XL = 2πfL, where L represents the inductance and f is the frequency of the AC signal.

The quality factor (Q) is a key parameter that reflects the efficiency of a coil. It is defined as the ratio of inductive reactance (XL) to the coil’s equivalent resistance (R), expressed by the formula: Q = XL / R.

A higher Q value indicates lower energy loss and better performance in AC circuits. Several factors can influence the Q factor, including the DC resistance of the winding, dielectric losses in the coil’s structure, energy dissipation caused by shielding or magnetic cores, and the skin effect at high frequencies. In practical applications, Q values typically range from tens to several hundred.

Parasitic capacitance refers to the unintended capacitance that forms between the turns of a coil, between the coil and the circuit board, or between the coil and any nearby shielding. This unwanted capacitance can lower the quality factor (Q) and reduce the overall stability of the circuit. To enhance performance and reliability, it is important to minimize parasitic capacitance during design and manufacturing.

– Single-layer coils

-Multi-layer coils

– Honeycomb coils

Air-core coil types can be classified according to the form of inductance into:

– Fixed inductance coils

– Variable inductance coils

Air-core coil types can be classified according to their operating characteristics into:

– Antenna coils

– Oscillation coils

– Choke coils

– Notch filter coils

– Deflection coils

Air-core coil types can be classified according to the nature of the conductive core into:

– Air-core coils

– Ferrite core coils

– Iron core coils

– Copper core coils

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.