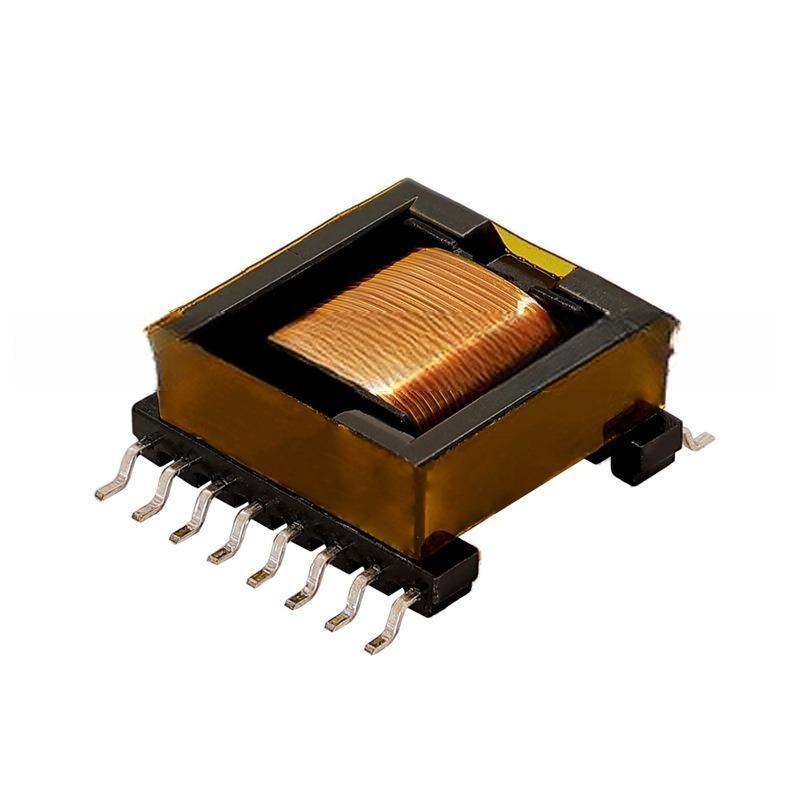

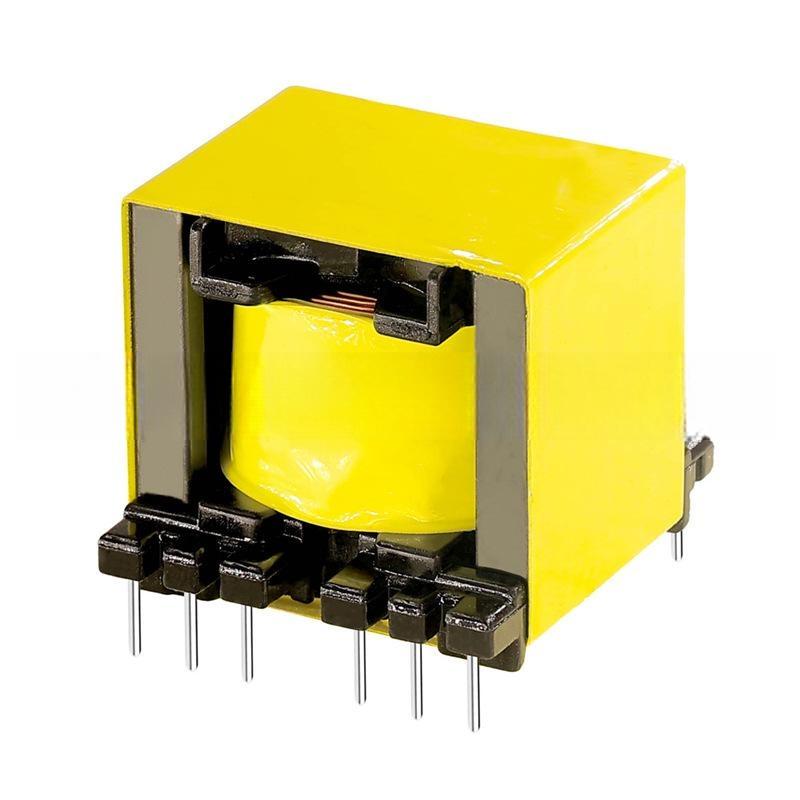

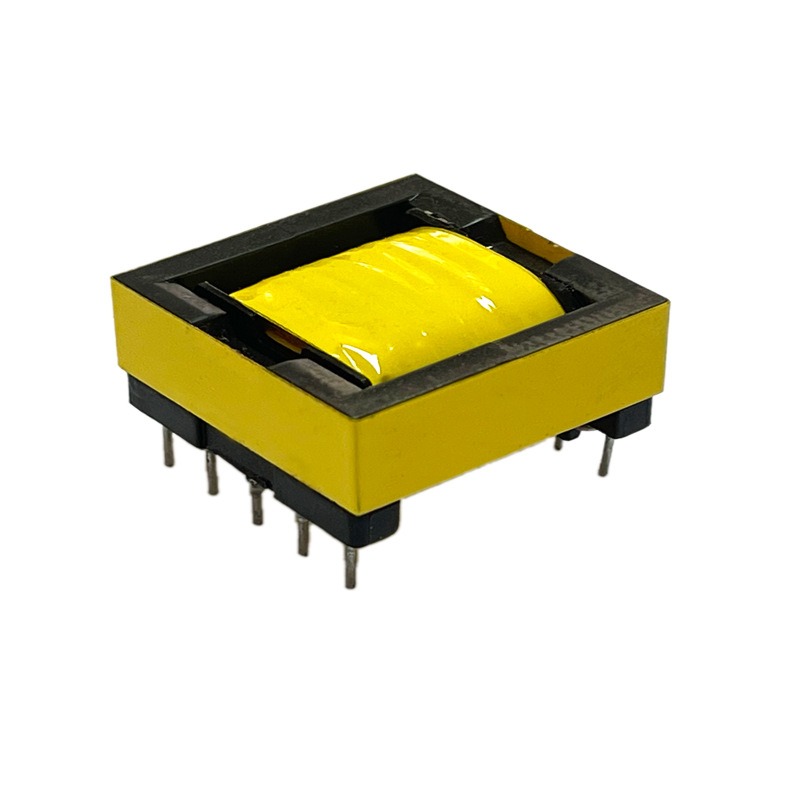

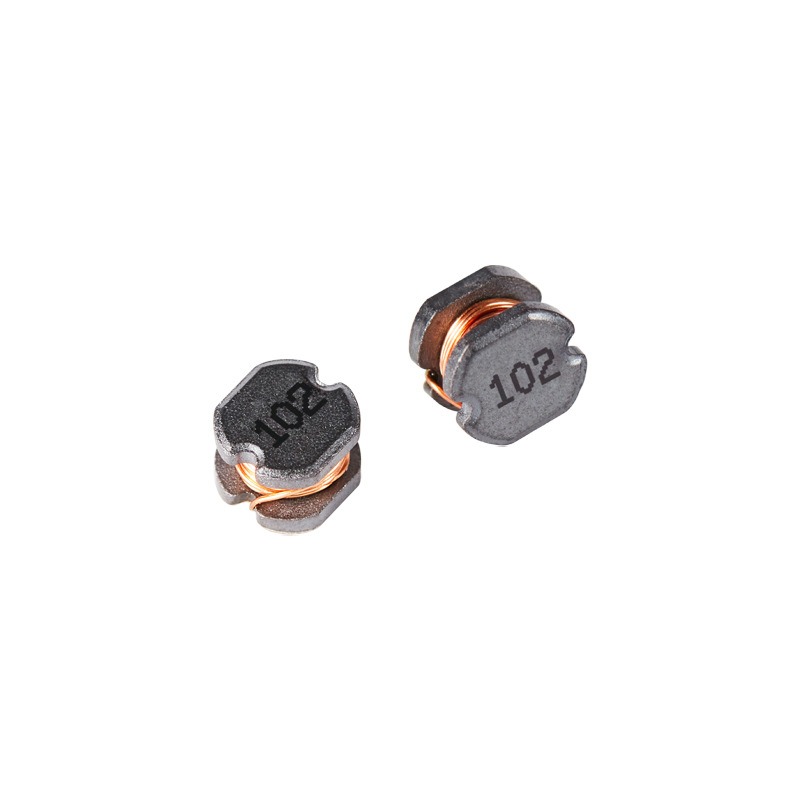

Key Points about the Custom Transformer

Custom Transformer refers to a transformer that is specially designed and manufactured according to specific requirements when standard models are not suitable for a particular circuit design. Since every engineer may have a different understanding of the circuit, the design of the circuit board often requires transformers tailored to meet unique specifications and functionalities. Therefore, we manufacture them based on the customers’ individual requirements.