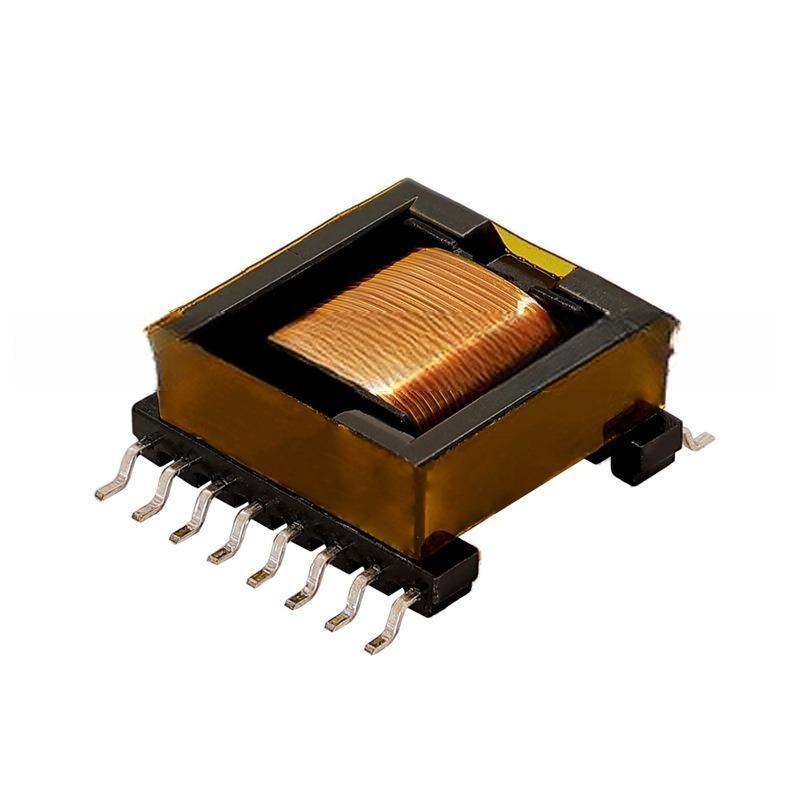

High frequency transformer is a power transformer whose operating frequency exceeds medium frequency (10kHz), mainly used in high frequency switching power supply . High frequency switching power supply transformer is also used in high frequency inverter and welding machine .There are many kinds of high-frequency transformer , such as EE type, EF type, EFD type , PQ type,RM type and so on.

High frequency transformer is a power transformer whose operating frequency exceeds medium frequency (10kHz), mainly used in high frequency switching power supply . High frequency switching power supply transformer is also used in high frequency inverter and welding machine .There are many kinds of high-frequency transformer , such as EE type, EF type, EFD type , PQ type,RM type and so on.

Transformers are used in all electronic products and the application of high frequency transformer is extremely wide. Its principle is easy, but transformer winding technology will have different needs due to different applications (different uses) .how to deal with the transformer short circuit incident ? What should be the first thing to consider when encountering problems?

First of all,we need to check the transformer accessories after the short-circuit incident .When transformer is short-circuit, the most likely deformation is the low-voltage winding and balance winding, and then the high and medium voltage winding, core and clip. Therefore, the transformer short-circuit incident is mainly to check the winding, core, clips and other parts.

First of all, checking the windings and experiment:

when the transformer occurs the short circuit, the winding together by pressure, pulling, bending and other forces under the effect of electric power, , the formation of the fault is hidden strongly and it is not easy to check and correct, after the short-circuit , we should view winding.

Secondly,checking the iron core :

Transformer core should have the mechanical strength. The mechanical strength of the iron core is to rely on the iron core on all the strength of the clamping parts and their connectors to ensure. When the winding power, the winding of the axial force will be offset by the clamping force, if the strength of the clamps, pull the plate is less than the axial force, clamps, pull the plate and the winding will be damaged.

Therefore, we should carefully check the iron core, clips, pull plate and its connectors. Transformer is to change the communication voltage, current and impedance equipment, when the primary coil with communication current, iron core (or core) in the communication flux occurs, so that the secondary coil induced voltage (or current). The basic principle of the transformer skeleton is the principle of electromagnetic induction. Transformer skeleton – the use of the principle of electromagnetic induction, from one circuit to another circuit transmission of electrical energy or transmission of signals is a kind of electrical appliances is the transmission of electrical energy or as a signal transmission of the important components.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.